TECHNOLOGY PATENTS

- Home

- Technology

- Robotic Welding

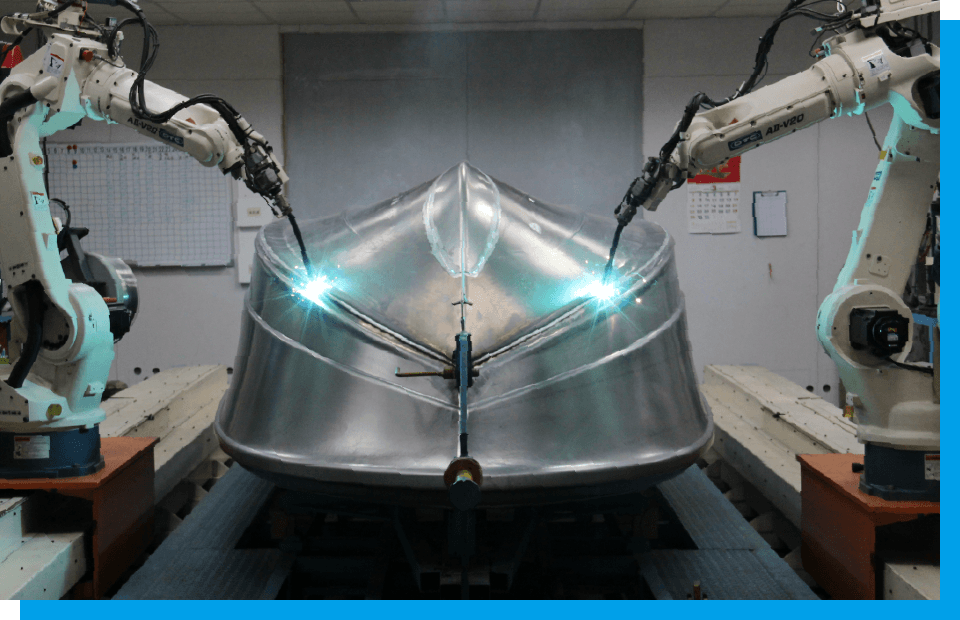

High-Precision Welding for a Strong Hull

Automated Robotic Welding

At Morningstar Boats, welding is performed by skilled craftsmen alongside automated robotic systems to ensure a durable and robust hull. Most of our production uses high-precision robotic arms and welding machines, delivering flawless welds every time.

Unique Forming Technology

Precision Craftsmanship for Perfect Curves

Using advanced forming techniques and high-precision laser cutting, each component is placed on an automated production line. Robotic arms follow programmed paths, guiding welding torches through precise points. CNC welding machines adjust key parameters automatically, ensuring consistently superior weld quality.

Standardized Production

Consistent, Zero-Error Performance

Adjustments to travel, current, voltage, arc, and oscillation are dynamic—changing multiple times per second. This precise, stable rhythm during welding cannot be achieved manually, ensuring flawless results every time.

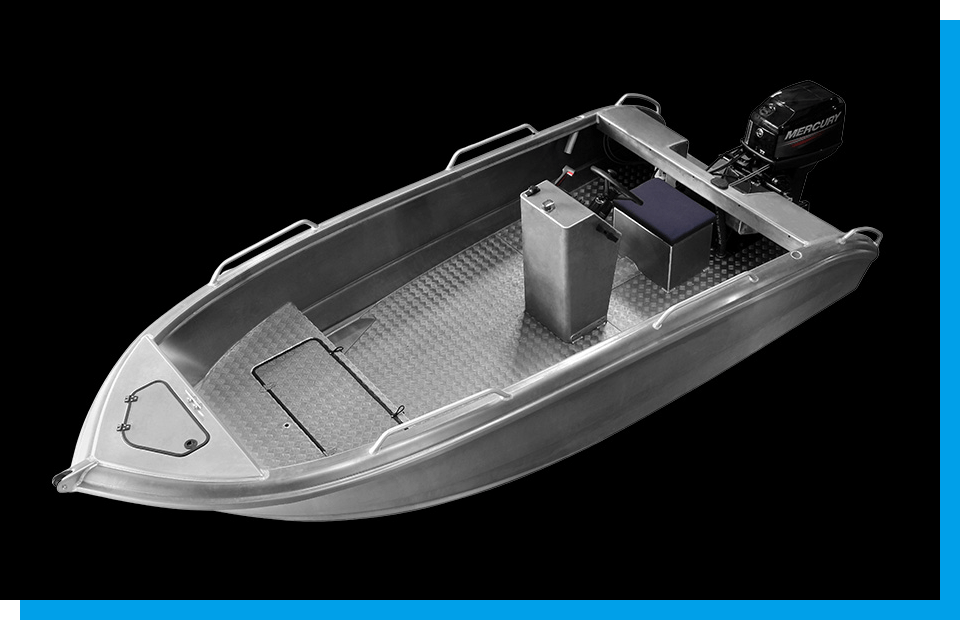

Product Quality

Thorough Testing for Zero Defects

Our standardized automated processes deliver highly consistent welds and stable quality, minimizing human error and variability.

During product development and quality control, we perform repeated destructive and non-destructive tests—such as X-ray and dye penetrant inspections. Certified inspectors trained by the Taiwan Welding Association and TCWI efficiently detect and correct defects, ensuring the highest welding quality for every vessel.

During product development and quality control, we perform repeated destructive and non-destructive tests—such as X-ray and dye penetrant inspections. Certified inspectors trained by the Taiwan Welding Association and TCWI efficiently detect and correct defects, ensuring the highest welding quality for every vessel.