TECHNOLOGY PATENTS

- Home

- Technology

- Hydro Hull M4

Revolutionary Aluminum Alloy Hull

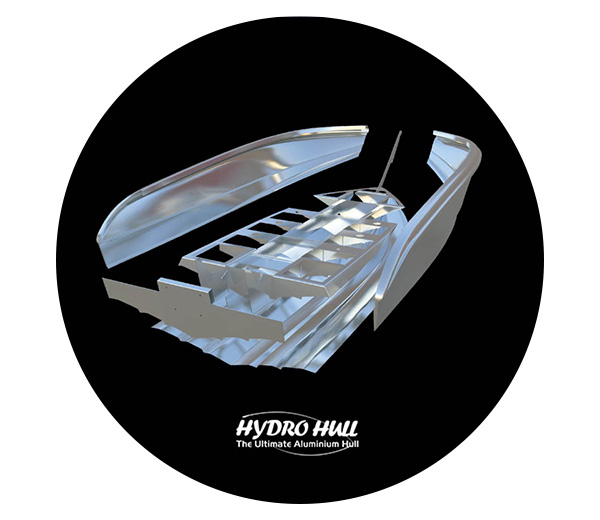

Hydro Hull M4

Hydro Hull is a groundbreaking aluminum alloy hull developed through years of blending traditional molding and shipbuilding techniques with modern digital analysis. Unlike conventional aluminum hulls, Hydro Hull retains the lightweight strength of aluminum while achieving the streamlined shape and hydrodynamic performance traditionally seen only in fiberglass boats.

Lightweight & Strong Aluminum

Fiberglass beauty & performance

Take the Hydro Hull as an example—marine-grade aluminum plates are shaped under thousands of tons of pressure to form advanced features typically found in high-performance fiberglass boats, such as reverse chines, strakes, and variable deadrise angles. These geometric elements enhance stability, wave-cutting ability, performance, comfort, and overall hull strength.

The same precision and innovation are applied to the side panels and transom deck. Finally, robotic welding fuses all components into a rigid, streamlined aluminum hull—Hydro Hull.

The same precision and innovation are applied to the side panels and transom deck. Finally, robotic welding fuses all components into a rigid, streamlined aluminum hull—Hydro Hull.

Streamlined Fiberglass Design

Aluminum strength & lightness

By adopting a one-piece molding technology that reduces the number of components, we integrate the side panels and hull structure into one, effectively eliminating many structural and welding defects common in traditional methods.

Complex curved hull designs that optimize hydrodynamics have long been exclusive to fiberglass boats. Due to manufacturing limitations, aluminum and other metal boats were restricted to simpler, developable surfaces.

With decades of metal forming expertise, our company has overcome these challenges to deliver hull shapes with outstanding handling performance.

Complex curved hull designs that optimize hydrodynamics have long been exclusive to fiberglass boats. Due to manufacturing limitations, aluminum and other metal boats were restricted to simpler, developable surfaces.

With decades of metal forming expertise, our company has overcome these challenges to deliver hull shapes with outstanding handling performance.